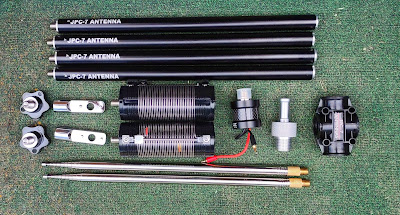

Rewinding the stainless steel coils with silver-plated copper wire on the JPC-7 and JPC-12 antennas

Portable antennas (verticals, loaded dipoles) typically use coils on the lower HF bands to make them electrically "larger" to alow them to be resonated at frequencies well below their physical size - but what about losses in those coils?

While it's "traditional" to use copper wire wire for these coils, there are a number of modern offerings that use stainless steel - and both types have their cheerleaders and detractors, so what's the deal?

|

| Figure 1: The JPC-12 vertical in the field. |

Note: This post refers to previous entries on this blog about the JPC-7 and JPC-12 antennas that are relevant to this discussion, namely:

While some details in this article are specific to these antennas, the general observations may be applied to any HF antenna using loading coils. I have not (yet?) done A/B field tests with antennas using different (stainless vs silver plated/copper) coils and/or simulations - perhaps a topic for a future blog entry?

* * * * *

In previous posts I have discussed the JPC-12 vertical and the JPC-7 dipole: To make either antennas usable at frequencies lower than their natural resonance, inductance is required (the "loaded" part) to achieve resonance at the desired frequency - and for their lowest operating frequency - 40 meters - it takes a fair bit of "loading", indeed.

For this, the JPC-7 dipole, which has a "coil-less" resonance of around 22 MHz, has two coils with adjustable taps - one for each element - a slider being used to adjust the amount of inductance: Higher inductance = lower frequency.

The JPC-12 vertical - made by the same folks - unsurprisingly uses the exact same coil as the JPC-7 - and for the same reason: To add inductance to make the electrically-short element - a radiator of approximately 150" (381cm) total length (resonant around 18 MHz without any added inductance and using the originally-supplied components) offer a semblance of a match on lower bands.

Having the coil in common, they also share the same trait: Loading coils wound with stainless steel - and since, when running on a lower band like 40 meters - all of these coils run quite warm at nominal transmitter power (100 watts or so) there are definitely power losses in the coil - but how bad is it?

Wanting to answer this question, I ordered an extra coil from the seller from which I'd bought my JPC-7 and JPC-12 antennas and with that - and the three that came with the two antennas originally - I now had four coils - enough to do direct A/B comparisons on both antennas when I rewound two of them with silver-plated wire.

Why stainless?

The coils originally supplied with the JPC-7 and JPC-12 are wound with 1mm diameter (18 AWG) stainless-steel wire. Fortunately, an austenitic (non-magnetic, as checked with a neodymium magnet) type of stainless steel is used: If this wire been magnetic at all things would be much worse in terms of loss. While the 1mm diameter stainless steel wire is very rugged physically, the fact that it is stainless steel means that its resistance is quite high compared to copper - in this case the end-to-end DC resistance is about 4 ohms, but the RF resistance, taking the "skin effect" into account, is likely to be very much higher.

Using Owen Duffy's online skin effect calculator (link) and assuming 1mm diameter, 316 Stainless, the 4 ohms of DC resistance translate as follows to RF resistance including skin effect:

- 3.5 MHz = 5.2 ohms

- 7 MHz = 7.2 ohms

- 14 MHz = 9.6 ohms

- 28 MHz = 13.6 ohms

Why stainless steel, then? Obviously, stainless steel won't oxidize/corrode like many metals - and it may be that in quantity, stainless steel wire is less expensive than silver plated/copper, but in this case I believe that there's another reason. Other manufacturers of portable antennas (Wolf River, for example) advertise the use of stainless steel for their coils as well, extolling the virtues of the material in regards to its inability to corrode - but I'd be surprised if such corrosion is likely to be the main reason for a hypothetical copper coil's losses in an electrically-short antenna that would make it worse than stainless.

I suspect that the "advantage" of a stainless steel coil is, in fact, related to the fact that it is lossy. As portable antennas - when used on the lower HF bands - are necessarily smaller than their full-sized counterparts, their radiation resistance will be commensurately lower and this means that the feedpoint resistance may be lower as well when fed with simple matching schemes such as a series coil.

What this means is that rather than somewhere "around" 50 ohms, the feedpoint impedance when using a very low-loss coil may be much lower, resulting in an "unacceptable" VSWR (e.g. >2:1) at resonance: While this would actually imply greater efficiency due to lower loss, it's "inconvenient" to the user. While a more versatile means of matching the antenna is possible (multiple coil/capacitors such as a simple antenna tuner or the use of an autotransformer) this complicates construction, operation and can increase cost.

As implied earlier, another method of dealing with low feedpoint impedances is to add series resistance to raise it to something closer to 50 ohms to make radios (and their operators) "happy" - but an ohmic resistance in the signal path (say, the use of stainless steel) means power loss, and power loss means heat!

How hot is it?

I've operated both the JPC-7 and JPC-12 antenna a number of times in the field on the "lower" bands of 40 and 30 meters at 100 watts, using both CW and SSB, and observed that in each case, the coil gets "hot". As the coil forms are (apparently) molded nylon, this is nowhere near the likely softening point of more than 300F (150C) - and being open to the air to allow convective cooling, and using a mode where the duty cycle is intermittent certainly helps prevent a "meltdown". (Compared this to PVC - which has a softening temperature in the area of 140-180F or 60-80C)

As a test, I put both the original stainless steel and the rewound silver-plated coils in series on the JPC-12 vertical, putting a jumper across the coil not under test. I then transmitted 75 watts into the JPC-12 vertical for 60 seconds and measured the temperature of the coil with an infrared thermometer and thermal camera, noting a temperature rise of about 110F (61C) - still not hot enough to risk melting the coil form, but certainly enough to dissuade one from running a 100% continuous mode like SSTV, RTTY or other digital modes on a hot day! (Note: On a hot day a temperature rise of 110F/61C may well be enough to soften a PVC coil form.)

The picture in Figure 2 - taken with a thermal infrared camera - shows the heat produced when testing with the JPC-12 vertical. (Note: During this test I swapped positions of the two coils to see if there was much difference in the current/heat of the stainless coil owing to differences in current distribution, but as expected, there was not.) Similar results were observed when operating SSB and CW on the JPC-7 loaded dipole.

At this point I should make something clear: The reader should not presume that the use of a stainless steel coil is going to result in an antenna that doesn't work, but rather it implies a degree of loss of efficiency. As I've made many contacts with both the JPC-7 and JPC-12 in their original form, I know that it's perfectly capable of usable performance - but how much better would it be if we were to address coil losses?

Also, once I had seen the loss in the coil, I couldn't "un-see" it and I had to do something about it.

Choice of wire

In order to minimize losses in an electrically-small antenna it is important to reduce resistive losses and the loading coil and reducing the generation of heat produced by it is a good place to start - and copper wire is an obvious choice. Knowing that the wire used is 1mm diameter - about 18 AWG - there were a lot of choices: I had some enameled 18 AWG wire already on-hand and I could easily have obtained some tinned 18 AWG "buss" wire as well. Finding bare copper wire was a bit more difficult, but since we need only make contact on the ends and along the slider, there's no reason for the entire coil to be bare and thus be subject to oxidization: If I needed to do so, I could have wound the coil with enameled wire and then selectively remove the insulation along the path of the inductor's slider with fine sandpaper.

On a hunch, I did a search and quickly found on Amazon some 1mm (18 AWG) "Silver plated" copper wire of the same diameter described as being used for jewelry - a small spool costing about US$15 with more than enough wire to re-do three of these coils. Footnote 1

Rewinding the coil:

The coil form itself - with molded grooves - is quite rugged and lends itself very well to being rewound by hand. Using a silver-colored "Sharpie" I noted where the original coil's windings started and ended. I would also recommend taking a photo of it - particularly if you are rewinding the coil of a JPC-12 vertical and do not have a second coil as a comparison.

It is also important to note that one end of the slider is insulated to prevent the shorting the unused turns of the coil itself - something that would surely reduce "Q" and overall efficiency: It is important to reinstall the slider assembly in the same orientation as before to put the insulated end of the slider rod on the "top" (e.g. the side closest to the top of the vertical or end of the dipole).

When rewinding, first move the slider to the end farthest away from the end with insulator on the rod (e.g. the "bottom" of the coil, with the stud protruding) and cover the spring contact with a bit of tape to keep it with the slider body: This moves the slider - and the contact spring - well away from the end of the wire that we are going to remove first. Using an Allen wrench, carefully remove the screw holding the end of the slider bar with the insulator (e.g. the part at the top of the coil, with the female threads): The end of the wire is tucked under the supporting post and the screw itself goes into the brass slug at the center of the coil with the M10 threads used to assemble the rest of the antenna. Keep tension on the hardware with a finger as you undo this to minimize the possibility of it being launched across the room.

With the tension released, remove the other end of the slider bar. At this point, carefully remove the slider bar from the insulated end so that you have just the support post and set the rest of it aside. At this point you'll have a loose coil of stainless wire to set aside.

At this point I temporarily wrap a the loose end of the coil with a bit of electrical tape to keep it from unraveling while I loosen the post at the top of the coil and align it carefully so that I can plug the slider bar back in and re-mount it and the other post at the bottom of the coil, torquing the screws firmly and being careful to prevent the post with the insulator from twisting as this is done.

Now, the coil has been successfully re-wound. While it may not be strictly necessary, I put a dab of "Shoe Goo" - a thick rubber adhesive - on the top and bottom 2-3 turns of the coil near where the wire drops into the slot and connects to the post to "glue" it into place, making sure that it doesn't jump out of its slot. If you don't have "Shoe Goo" or something similar, some RTV ("Silicone") can work as can epoxy - but cyanoacrylate and polyurethane glues (e.g. "Super" and "Gorilla" glue, respectively) may not work very well - and "hot melt glue" are definitely not recommended as either will likely break loose their bonds across a wide temperature range and changing mechanical stress.

The trick here is to bridge several turns of wire with the adhesive to lock them into place together as much as adhere them to the coil form.

Results

Touching the coil immediately after the 60 second key-down, the loss-related heating of the coil wound with silver-plated wire was barely perceptible - a far cry from the original stainless-steel wound coil that was "hot"!

Electrical comparison of the stainless and silver-plated coils

For capacitors and inductors, one measurement of their departure from the ideal is their "Q" (e.g. "Quality Factor") and for inductors, the majority of this is likely to be the radio of the inductive reactance of the coil (XL) to its ohmic resistance. I decided to measure the unloaded "Q" (Qu) of the original stainless steel loading coil and the rewound silver-plated coil. To do this I used a NanoVNA and the method described in W7ZOI's article "The Two Faces of Q" (link) under the section called "Measuring Resonator Q": I used both methods (#1 using parallel L/C and #2 with L/C in series) to determine the "Q".

Using method #1, for the "Cc " capacitors I used two 1pF NP0 capacitors in series each (0.5pF) which resulted in a 35-45dB through loss at resonance. I put a high-quality 27pF silver mica capacitor in parallel with the coil under test and measured the -3dB response of the resonance curve. In this test I set the variable inductor to the mark indicating tuning for 40 meters (around 22 uH) which, with the 27pF capacitor, yielded a resonance in the area of 6.6 MHz for each of the two coils being tested

Assuming that the Q of the series silver mica capacitor (Co) is 1000 (a mediocre value - it's probably a bit higher) the results were:

- Original stainless steel coil unloaded Qu: 47

- Rewound coil (silver-plated wire) unloaded Qu: 199

I then used method #2 (with L/C in series) and got:

- Original stainless steel coil unloaded Qu: 47

- Rewound coil (silver-plated wire) unloaded Qu: 221

At the risk of being accused of "cherry picking" my results, I'll note that for high "Q" values and where the value of Co is quite small, method #1 is less forgiving in terms of variances and minor losses in the test fixture, so we'll use the value from method #2. The reader should also note that with a higher Q, deficiencies in the test measurement and effects of the coil itself will result in lower than actual Qu (e.g. you will not get an erroneously higher value of Q) so it is likely that even the higher reading from method #2 on the silver-plated coil is, itself, a bit conservative.

Note: During testing I observed that just laying the coil on my wooden workbench lowered the Q of the silver-plated coil significantly (15-20%) so all readings were taken with both coils held about 12" (25cm) above it. I think that there is likely some effect of free-space capacitance that is reducing the reading so I suspect that the "actual" Qu of the silver-plated coil is higher, still. This same effect was extremely small with the stainless steel coil, further indicative of its lower Qu.

Comment: It's worth mentioning that with higher "Q" coils, the physical aspects of the coil itself - namely the ratio of the length versus diameter, spacing between turns, material of the coil form, increasingly affect the Q - both for reasons of geometry (which can affect the amount of wire needed) and less obvious parameters such as distributed capacitance, etc.

- Q = XL / R

Or the more general form, knowing the inductance:

- Q = 2π f L / R

And rewriting this equation for R we get:

- R = 2π f L /Q

So, for a frequency of 6.6 MHz (which should be representative of 40 meters) and an inductance of 22uH, XL is approximately 912 ohms, so for each of the two coils the apparent "R" value - which would be a combination of conductor loss and skin effect resistance we get:

- Original stainless steel coil: R= 19.4 ohms

- Rewound coil (silver-plated wire): R=4.1 ohms

The reader should be reminded that for ideal components, at resonance the reactance of the inductor is losslessly canceled out by the reactance of the capacitor so what we are left with - the value "R" mentioned above - will be the ohmic (conductor loss + skin effect) losses of the materials. This also means that the "R" value will be added to the feedpoint resistance - and the effect of this "R" value is to lose power as heat as we will see below. It is not lost on me that the loss values appear to be far higher than those obtained from Owen Duffy's calculator if one presumes skin effect to be the main source of loss - which we know is not going to be the case.

The ohmic loss mentioned above is not going to be the only source of loss in a real antenna system: In the case of a vertical, the "ground" losses (ohmic loss of radials, dirt, etc.) and with any antenna, the materials from which it is constructed (wire, telescoping rods which are themselves stainless steel, any balun being used, etc.) will come into play - and for an "electrically small" antenna such as either the JPC-7 or JPC-12 on 40 meters, will dominate and probably be the main points of loss besides the coil.

This goes to show how - in either case - doing anything to physically "embiggen" the size of the antenna - such as making the elements longer (adding drooping wires to the loaded dipole, adding a tophat to the vertical) will reduce the amount of inductance needed and increase the radiation resistance - both things that will contribute to improved efficiency.

With the stainless coil, it gets worse the lower you go!

Out of curiosity I re-did the Qu measurements using a 270pF silver mica capacitor - which lowered the resonant frequency to about 2.2 MHz - and got the following results using method #2:

- Original stainless steel coil unloaded Qu: 29

- Rewound coil (silver-plated wire) unloaded Qu: 277

Given the lower frequency and lower skin-effect losses I fully expected the loaded Qu to be slightly higher - which is true for the silver-plated coil - but initially I did not expect the Qu to go down on the stainless steel coil so I re-did the measurement using method #1 and got about the same results (to within a few percent) - but in retrospect, I realized that this was to be expected.

As QL can be defined as being the ratio between inductive reactance ( XL ) and skin effect and ohmic resistance (R), if "R" remains pretty high and XL lowers with frequency, the "Q" will be lower: Since the resistance of the stainless steel wire is so high to begin with, it figures significantly in the reduction of Q and thus the losses incurred.

In perusing the forums in the back-and-forth discussions about stainless steel versus silver-plated coils, people have observed a "hotter" coil at the lower frequencies. At first glance, this makes sense since lower frequency = "more coil" = more lossy wire - but the fact that - at least at HF - the Q of the stainless coil goes down significantly with frequency makes it even worse!

Update:

I recently got my HP-4191A RF Impedance Analyzer online and did some direct measurements of the coils and capacitors. Unfortunately, at the 22uH inductance and 2.2 or 6.6 MHz, this instrument doesn't do too well (it wasn't designed to fully analyze such high inductance at those frequencies), but it fares much better with the 27 and 270pF capacitance values at these same frequencies.

Using the '4191A I measured the "Q" of the 27pF at 6.6 MHz as being

237 - but the Q did easily exceed 1000 in the area of 9-11 MHz. Meanwhile, the 270pF capacitor had a measured Q of 267 at 2.2 MHz and it, too, exceed 1000 at some frequencies.

As the Q of the silver mica capacitors mentioned above were assumed to be 1000, we can now use a known value for the capacitor's Q and recalculate the measured Qu of the L/C combination, which yields, using method #2 with the 27pF capacitor at 6.6 MHz, above as:

- Original stainless steel coil unloaded Qu: 55

- Rewound coil (silver-plated wire) unloaded Qu: 766

Similarly, at 2.2 MHz using the 270pf capacitor:

- Original stainless steel coil unloaded Qu: 32

- Rewound coil (silver-plated wire) unloaded Qu: 1156

As expected, the measured unloaded Qu of the stainless steel coil didn't change by a huge amount, but the calculated Qu of the silver-plated coil certainly did!

If the capacitor Q values are taken at face value, we can come up with new values of "R" for the coil loss at 6.6 MHz:

- Original stainless steel coil: R= 16.6 ohms

- Rewound coil (silver-plated wire): R=1.2 ohms

* * *

Testing with the JPC-12 vertical and JPC-7 loaded dipole.

As noted earlier, the rewound coil was initially tested on the JPC-12 loaded vertical on 40 meters - mostly because it uses only a single coil and at that time I had rewound only one with silver-plated wire. While I was at it I decided to see if I could detect any difference in the current flowing through the coil at a given RF power output related with the use of the original (and lossy) stainless steel coil and the silver plated coil. Again, figure 7 shows this rewound coil with a thermal infrared camera just after a 60 second key-down at 75 watts, the temperature rise being just 3F (<2C).

Let us now consider the measured resistive losses of the coil (let's say 20 ohms for the stainless coil, 4 ohms for the silver-plated one) at 75 watts - the power at which we observed the temperature rise. As we know the approximate current to be expected (about 600mA at 20 watts as measured with a known-accurate thermocouple-type RF ammeter) we can calculate the apparent losses at 100 watts which would equate to about 40 watts for the stainless coil and 5.7 watts for the silver-plated coil. What this means is that nearly half of the power is lost in the stainless steel coil - but this still represents less than 1 "S" unit of loss. Footnote 2

Note: Judging by the ratio of the temperature rise between the two coils (3 degrees F for the silver-plated coil and 110F for the stainless) we would expect far greater difference in power loss between the two coils (more than 30-fold difference, so I'm likely missing something here).

Update: Based on the revised "Qu" measurements mentioned above (e.g. Q=766 with R=1.2 ohms at 6.6 MHz) the calculated thermal loss for the silver-plated coil is estimated to be 2.2 watts rather than 5.7 watts.With the original stainless steel coils, the feedpoint resistance at resonance is "close enough" to 50 ohms to keep a radio without a tuner happy (it's actually lower than 50 ohms as noted below) - but consider that this means that each half of the dipole is closer to 25 ohms, the two being in series with each other: With two coils' losses now in the mix - and the fact that a given loss of a coil in a 50 ohm circuit as a percentage was about half that of the same amount of resistance in a 25 ohm circuit - the losses are arguably worse, but "split" between the two elements.

While I didn't have the opportunity to use the thermal infrared camera to measure the temperature rise of the stainless coils on the JPC-7, they both got rather hot to the touch after key-down at 75 watts, indicating a roughly comparable amount of loss as did the original stainless steel coil on the JPC-12 vertical: As with the vertical there was little change in temperature of the silver-plated coils.

Using a NanoVNA and minimal coax length Footnote 3 I set up the JPC-7 as per the the manufacturer's instructions on 40 meters: From the feed point there were two mast sections, the coil and then the telescoping rod on each side. Carefully setting the coils and the element lengths to yield the lowest "R" value (e.g. at resonance), I then noted the "feedpoint" resistance at resonance (where reactance, or "J" = 0) using the stainless steel and then the silver plated coils:

- Stainless steel coils: 38 Ohms (1.32:1 VSWR)

- Silver plated coils: 15 ohms (3.4:1 VSWR)

It's worth noting that these "feedpoint" readings were taken with the supplied 1:1 balun inline along with a short length of coaxial cable so the above readings are NOT precisely those of the actual feedpoint resistance: There is likely a bit of loss and transformation occurring in the aforementioned set-up so the absolute numbers above may not reflect the actual feedpoint resistance itself. I also observed that on the JPC-7, the (normalized) 2:1 VSWR bandwidth was lower with the silver-plated coil - an expected effect with higher Q resonator coils.

Note: On higher bands (e.g. 20 meters and up) the feedpoint impedance was much closer to 50 ohms with either coil and it's likely that nothing special will need to be done to keep a radio "happy".

One might be tempted at first to think that because of the higher VSWR,the silver plated coil constituted an antenna that was "worse" - but that would be wrong - this actually indicates the opposite. What this measurement shows us is that the apparent total resistance of the two silver plated coils at 40 meters was 23 ohms less (about 11.5 ohms for each coil) than that of the silver plated coil - and this increased resistance is what accounts for the power being lost as heat.

This realization still leaves us with the problem that if we take away much of the loss of the coils we lower the feedpoint resistance which means that we can end up with a rather high VSWR - of over 3:1 - meaning that many radios won't be particularly happy with the situation without throwing a tuner into the mix. This leaves us with several options:

- Pretend we didn't see this and continue using the stainless steel coils. This is an obvious choice and I can attest that both the JPC-7 and JPC-12 antennas do work pretty well despite the loss of the coil, but personally, I can't "un-see" the lossy nature of these coils, so that's not an option for me. As a "portable" antenna is all about compromise of performance, I prefer to minimize the deleterious effects of as many aspects of this "compromise" as I reasonably can.

- Use an antenna tuner. Placing a tuner at the antenna is the preferred choice as it will minimize mismatch losses that will result if the tuner is placed at the far end of the cable feeding the antenna (e.g. in the radio.) Whether the magnitude of mismatched loss of the cable when the tuner is placed at the distal (radio) end of the feedline to match the lower-loss silver-plated coil is worse than using no tuner at all with the stainless steel coil cannot be easily answered without knowing the properties of the coax used and how a specific tuner works under the impedance conditions that it might see.

- Rework the balun. The JPC-7 has a 1:1 balun (one that isn't very "balanced" - but that's another topic) but it is clear that you could choose a balun that inherently provides a suitable transformation - but more than one such balun would be required to cover all bands.

- Autotransformer. A tapped autotransformer used to be a common "thing" many years ago for matching short verticals (e.g. mobile installations) to deal with the low feedpoint resistances at resonance - often well under 20 ohms for a low-loss coil. These devices seem to be less common these days, but if you look carefully they may still be found on the surplus market - namely the Atlas MT-1 and Swan/Cubic/Siltronix MMBX, both of which offer selections of impedances that will easily yield 1.5:1 VSWR or better at any likely feedpoint resistance at and below 50 ohms. I have tested the Atlas MT-1 (by putting two units back-to-back) and found a single unit to have about 0.2dB of loss on 40 meters which theoretically represents about 5% power loss. (Useful articles about RF autotransformers may be found in the November 1976 issue of "Ham Radio" magazine - link and the December, 1982 QST - link.)

As mentioned previously, the losses of the stainless steel coil are "about an S-unit" on the lower bands so the user would have to weigh the benefits of the potential losses incurred by matching a silver-plated coil and additional matching versus just using the stainless steel coil and getting a more convenient match and just "eating" the losses.

Conclusion:

The reader should not go away thinking that antennas using loading coils wound with stainless steel wire don't work: They do - and can be quite effective - but...

In my measurements, the losses added by the stainless steel coils amounted to roughly "an S-unit" (more or less) in a worst-case situation for the vertical antenna and somewhat more than this for the loaded dipole. I have very successfully used both antennas with their original stainless steel coils for portable, remote and POTA operations with good results. The difference of "about an S-unit" may be an issue for marginal situations using SSB, but it's less likely to be a problem for CW or digital modes under the same band conditions and distances where the signal margins are more favorable for weak signals.

As electrically-small HF antennas will often have lower feedpoint resistance than their full-sized counterparts this means that intentionally using low-loss coils can shift the impedance well below 50 ohms, complicating the matching of the radio to it - particularly in the case of the loaded dipole: The use of a radio's built-in antenna tuner - particularly with a long length of coax - may well incur losses greater than those of the lossy stainless steel coil without a tuner.

I'm guessing that the use of stainless steel wire for the coils is at least partly a result of it "simplifying" the operation of a portable antenna by resistively (lossily!) providing a feedpoint resistance closer to 50 ohms. From a standpoint of operational simplicity and cost (both avoiding more complicated matching arrangements) the use of stainless steel - and simply "eating" the power loss - may be a reasonable compromise for most users.

But, it's not as simple as that. The above is certainly true for the loaded dipole where the feedpoint resistance ends up being quite low (15 ohms on 40 meters) but for the vertical - where more variables are at play (e.g. lengths of radials, length of vertical resonator) one can easily attain a good match (<2:1) to 50 ohms even with the lower loss of the silver plated inductor coming into play.

All of the above should also point to something else: In my respective articles about the JPC-7 and JPC-12 antennas I noted that performance could be improved by making them electrically "larger" (e.g. the addition of a top hat to the JPC-12 and "droop" wires on the JPC-7) which both reduces the amount of loading inductance and likely increases the feedpoint resistance - both of which contribute to improved efficiency.

Should you toss or rewind your stainless steel loading coil in favor of something using lower-loss material? If you are trying to eke out every last bit of efficiency from your portable antenna and are prepared to deal with the possibility of slightly more complicated matching requirements (at least on the lower HF bands like 40 and 30 meters) to deal with potentially low feedpoint resistance - then perhaps. If you operate a lot of SSB, operate using high power (>= 100 watts) and/or high duty cycle, it may well be worth doing what you can to reduce at least one of the sources of loss of these types of portable antenna systems and a potential failure point due to heat.

* * * * *

Footnotes:

- This silver-plated jewelry wire that I used is varnished, so it's not actually bare - but this poses no problem with this project: The protective coating is pierced when the new wire is clamped under the posts and the slider easily "bites" through it, so there is absolutely no need to strip it. The varnish on the rest of the coil offers protection from oxidation and while silver oxide is a reasonably good conductor, unoxidized silver is much better, so the coating is left intact.

- The term "S Unit" is occasionally used in this article, but always with a bit of "hand waving" indicative of its ambiguity. An "official" international definition of an S Unit is a 6 dB difference in signal level according to IARU Region 1 Technical Recommendation R.1 (where "S9" = -73dBm into 50 ohms - link). While U.S.-made radios and many SDR programs use this definition by default, Japanese radios are often calibrated with 3 dB S-units meaning that for these radios, smaller amounts of signal change are more strongly indicated. The reader should always note that while modern SDR-based receivers often do have reasonably good relative signal indications (e.g. the S-meter moves as it should for given changes in signal level) this is likely not true for older, analog radios.

- For both transmitter and VNA testing, minimal coax length was used. For the former, a very short (15cm) coax jumper was used, connected directly between the radio and the antenna feed, the radio being powered by battery. For the VNA, the instrument was connected similarly - the 15cm coax for the JPC-12 and hanging directly from the JPC-7's balun - to minimize possible effects of common-mode RF currents on the antenna. In real-world operation this would be emulated by using an effective common-mode choke as close to the antenna feed as possible.

- Observations, analysis and field use of the JPC-7 portable "dipole" antenna - link.

- Observations, analysis and modifications of the JPC-12 vertical antenna - link.

- "The Two Faces of Q" by Wes, W7ZOI - link.

- About Q-factor of RF inductance coil - link.

- High-Q RF Coil Construction Techniques by Serge Stroobandt, ON4AA - link.